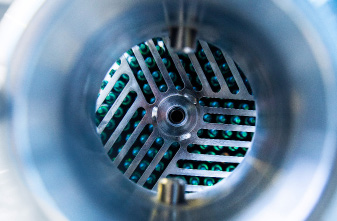

The large, regulated electric utility referenced in this case study provides clean, safe, and reliable energy across 16 states in the United States. Included in its power generation is nuclear power fleets, a highly available and reliable energy source aiding in global net zero carbon goals.

Nuclear fleets require structured processes, detailed information, visibility, and efficiency in order to operate safely and reliably during online operations or during outages.

Organizational alignment is critical to maintaining efficient processes, incorporating best practices, and making data driven decisions that best serve customers and organizational growth.

The utility approached Cohesive in early 2023 with specific regards to the scheduling and work management practices across their Nuclear Fleet, which had shown inconsistencies and process gaps. Additionally, the organization’s current

technology was functionally deficient in helping to facilitate and optimize this process.

Aligning best in industry scheduling practices with the use of modern technology to integrate and automate the process was also a key in the clients’ scope of work.

Applying Modern Maintenance Strategies to Nuclear Work Management

Initiate, Plan, Execute and Close.

- Recommendations for process changes and guidelines

- Changes in Maximo structure

- Modernization of scheduling integrations

- Strategic technology upgrades

Increasing Operational Efficiencies Through Modernized Scheduling Practices

Cohesive brings a holistic approach to clients when providing recommendations for change. As an industry leader, the deep expertise in process and best practice is balanced with technology, personnel behaviors, and training and change management to ensure effective, sustainable

solutions that continue to support the organization.

After the engagement, Cohesive provided the client with a strategic assessment and guide to create a transformed scheduling and work management program that will:

- Increase productivity

- Improve risk recognition and mitigation

- Improve governance and oversight

- Modernize technology

- Drive resilient operations