A Strategic Partnership to Drive Clean Energy

This electric utility corporation services power to 10 million people through Tennessee and additional surrounding states of the southeast.

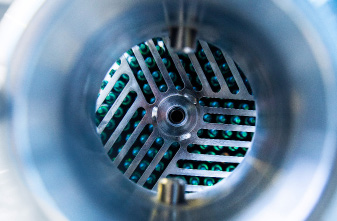

Their energy portfolio consists of various types of power generation assets from fossil, hydroelectric and solar to nuclear power plants.

Much like Cohesive, this organization is dedicated to The Nuclear Promise and advancing Nuclear Power forward to support global clean energy goals.

As part of this, they formed a specific new nuclear group to manage the efforts surrounding the design and construction of Small Modular Reactors in their region. Optimizing cost and timeline during constructions and throughout future operations and maintenance (O&M) phases is one of the biggest drivers helping advance the industry and making nuclear power a more feasible and widespread solution for clean energy.

Strategizing Future Operational Efficiencies in the New Nuclear Design Phase

This client sought out Cohesive’s expertise to evaluate and optimize future O&M costs while in the project’s design , to ensure the plant was set up to ensure their operating costs

are met even years before the physical assets would be put into service.

are met even years before the physical assets would be put into service.

This type of analysis and planning for future state outcomes requires deep expertise in both the industry and modern maintenance tools and strategies.

Cohesive is working with the client throughout the design and construction of this project tools to analyze and evaluate designs for maintenance, training and resource requirements throughout the operations cycle, to create excellence in the O&M process that would drive down cost and increase efficiencies.

Cohesive’s partnership is guiding them to better, more optimized outcomes through the data, technology and process enhancements within modern maintenance strategies.

Driving Condition Based Maintenance in New Nuclear Design

To achieve future operational optimizations, Cohesive is applying smart maintenance tools and strategies to their design phase. Smart Maintenance, a pillar of Modern Maintenance, is the concept of performing the correct maintenance at the correct time, with the correct personnel. Maintenance is moved from a reactive domain into a proactive and predictive domain using analytics, artificial intelligence, and machine learning.

Cohesive leverages their deep understanding of asset reliability and performance, nuclear construction and operating requirements, digital technology, and data management to create a tailored, phased approach based on design maturity and project timeline to drive transformations and deliver value for this energy provider and their new nuclear project in a timely manner.

Future-Proofing Small Modular Reactors for Operational Optimization

Adopting a modern maintenance strategy and implementing a smart maintenance approach to maintenance will allow the nuclear group to plan their Operations and Maintenance activities long before the plant is built, resulting in

optimized work and reduced personnel required on-site to perform.

optimized work and reduced personnel required on-site to perform.

Any time a plant can achieve this type of O&M optimization, the efficiency and cost savings are significant, which is critical especially in this first of- its-kind reactor design.

It’s partnerships like this that will continue to advance industry and help our planet rely on clean energy.

A Partner in Nuclear

Cohesive’s roots in Nuclear run deep. We partner with new nuclear and operating organizations to align deep industry expertise that spans across the entire nuclear lifecycle, with cutting-edge modern maintenance practices and technologies that drive better, more sustainable outcomes

for nuclear.